The quality of your project depends on the quality of the steel supporting it. That’s why so many owners, contractors and service centers depend on the proven strength of products from Atlas Tube.

Every facility features a full metal lab for product testing to guarantee quality. We perform mechanical testing for yield, tensile and elongation. Additionally, we perform destructive and non-destructive testing to verify the integrity of the weld.

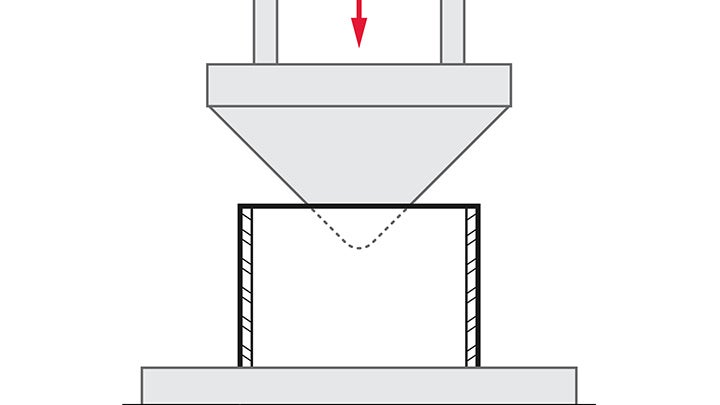

This method of destructive weld testing occurs during production to verify the weld’s integrity and ductility. During cone testing, a hydraulic press forces a pipe sample over a cone until either the test piece fails or the end expands to a predetermined size without weld failure.

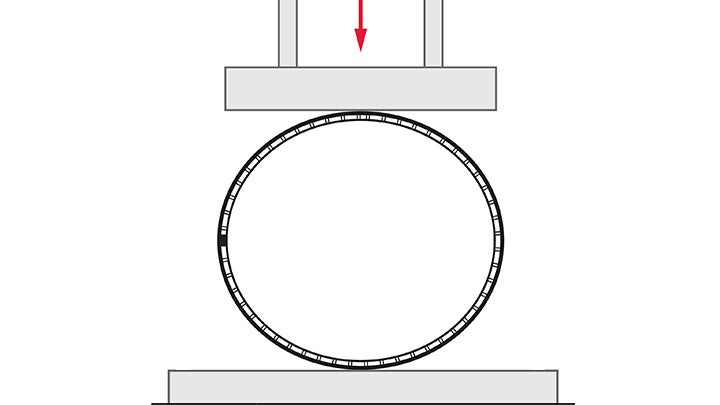

This destructive test also occurs during production to verify the integrity of the weld and the ductility of the parent metal. During flatness testing, a pipe sample is flattened with the weld at the vertical and horizontal axes (0° and 90° from the direction of force).

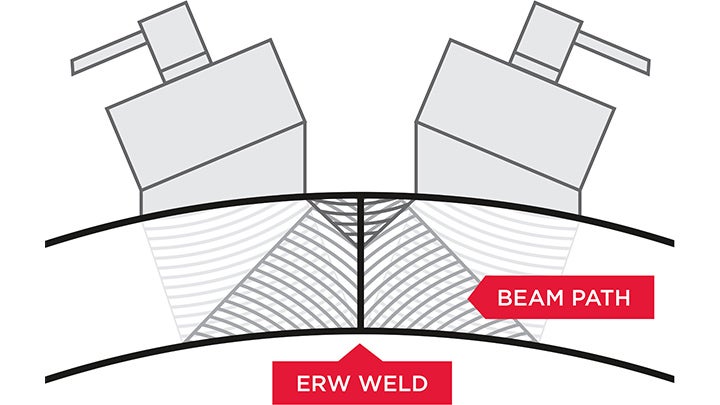

This non-destructive testing (NDT) method checks weld integrity during manufacturing. Ultrasonic inspection can detect the presence of internal flaws by transmitting high-frequency ultrasonic sound waves through the tubing and evaluating characteristics of the returning sound. The discovery of a defect triggers an automatic marking system that indicates the location of the problem. The defective piece is then cut out and rejected at the end of the mill.

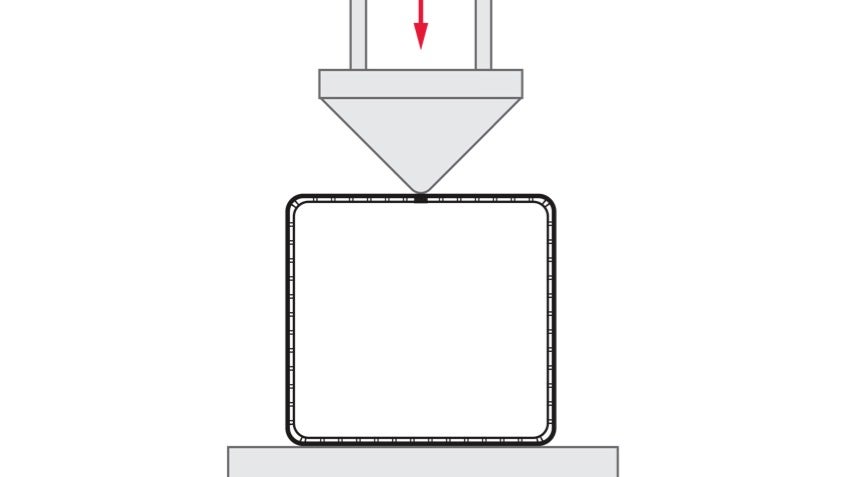

This is a destructive test of the weld for shaped material to ensure weld integrity, especially on pieces that are too large for cone testing. A hydraulic wedge is pressed backwards into the weld to ensure it is sound and that there are no cracks in the outside or inside diameter.