At Atlas Tube, we provide comprehensive documentation to prove the industry-leading quality of our ERW steel pipe products. Mill test reports, tag data and ID stamping allow for material traceability across all steps of the product lifecycle.

We issue an original MTR for every bundle produced at each of our facilities. MTR documentation includes complete heat traceability, chemical analysis, tensile properties and Charpy impact testing (if applicable). Every MTR is backed by coil certificates from the raw-material suppliers, which are reviewed before the coils ship to us so we know the steel meets the highest quality requirements.

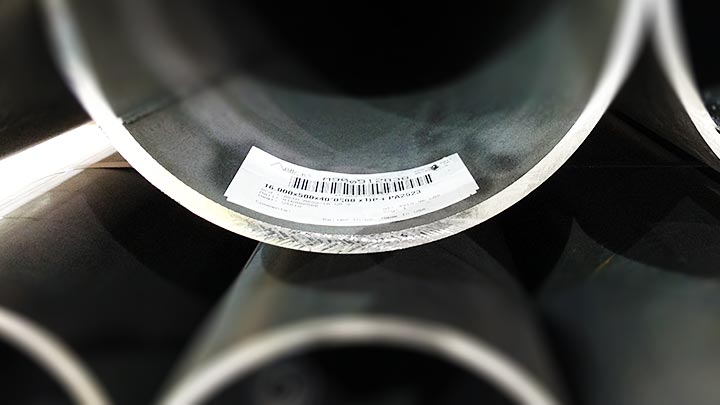

We’re the only manufacturer that includes a tag tack with each product bundle. The tag allows for traceability, helps us verify production information if questions arise, and makes storage easy.

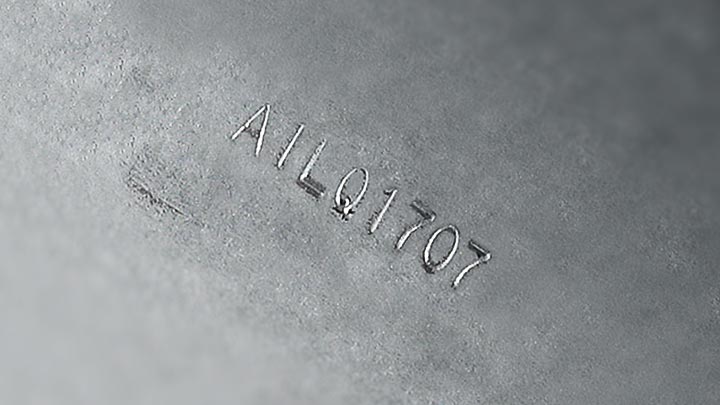

To ensure complete traceability for U.S. projects, we stamp our American-made piling products every 38 inches across from the weld. This way we know exactly where and when it was manufactured, even after the product is coated or the stencil wears off.